This feature is part of a series focused exclusively on learning technology. To view other posts in the series, check out the spotlight page.

Blue collar employers need help.

When the HR industry talks about skill gaps, the conversation tends to focus on those seen in emerging, high-growth industries like artificial intelligence, or in other STEM fields like medicine and nursing.

As valid as those gaps may be, this focus largely ignores what’s going on in long-standing, storied industries like manufacturing, construction and trucking. The dynamics of employment in these industries aren’t just confined to the communities that depend on them; blue collar workers played a pivotal role in the last presidential election and are a key part of defining many employer-oriented laws and policies.

Certainly, there are shortages in states like Pennsylvania, Michigan, Ohio and Indiana. But there’s also a fundamental misunderstanding at play: Workers on the whole suffer from a lack of competency, not a lack of job openings.

This is creating fears that, regardless of the number of jobs American companies produce, millions of them may go unfilled. Some of the nation’s top CEOs even acknowledged this in a meeting with President Donald Trump in February.

So how best to address their concerns? For L&D leaders in blue collar fields, the solution is clear: Get workers up to speed for their current job — and help them develop the skills that might land them their next one.

“No one fixes their own car anymore”

How do we begin to account for gaps in the industrial workforce? A common explanation is the fact that business investment in emerging technology has outpaced that of worker training.

As MPC Consulting President Michael Collins explained in a post for IndustryWeek, such programs became one of several causalities as far back as the 1980s when, in an effort to decrease the costs of production, many businesses began to "eliminate functions that they didn’t see as core competencies."

Among those items largely deemed non-essential? Long-term training programs. "In this process, apprentice-type training was lost in many American corporations," Collins wrote, "because it is long term training and doesn’t have a 'good' ROI."

For learning technologists at LearningSI, a training program firm that specializes in industrial applications, it's not just a lack of investment. The fact of the matter is, many workers in affected fields haven't had the same introduction to industrial concepts prior to entering the workforce.

Or, as LearningSI e-learning expert Brendan Nagle succinctly put it: "No one fixes their own car anymore."

"You know, that sounds funny," LearningSI CEO Steve Ostrowski said after hearing Nagle's remark, "but that was a very basic way to learn about mechanical concepts." Ostrowski said several clients have come to his firm complaining that their new hires, or lack thereof, simply don't have the necessary skills to do a given job.

"It isn't just that they don't know how to insert 'tab A' into 'slot B' — it's because they don't actually have the foundational knowledge to understand why they would need to do that," Nagle said. "Sometimes unpacking what the actual problem is is a problem in and of itself."

That's part of the reason why LearningSI places an emphasis on e-learning content that specifically teaches fundamental skills applicable to industries ranging from oil refining to electrical engineering. Courses include primers on instrumentation, basic physics and pumping among others.

"We'd like to think we provide more than training," Ostrowski said. "If someone learns something, then they're prepared to anticipate. In the process industries especially, it's extremely important that people are prepared to anticipate that they can prevent problems."

Tech upgrades on the horizon — if you can afford them

When Pokemon GO took the world by storm nearly a year ago, HR pros took notice. The viral hit seemed to signal a cultural arrival for the concept of gamification — a term that has become something of a buzzword for L&D professionals.

The speculation is understandable; what if blue collar learning could utilize augmented reality (AR) or virtual reality (VR), or some combination of both?

"Gamification is certainly a strategy for developing new hires," said Bill Docherty, VP of Product Management for SumTotal. He explained the story of one client who set up training in an Amazing Race-style form, placing tidbits of information in different areas that had been directed toward specific roles.

"In many industries, if you go into a hazardous area, phones and iPads aren't particularly safe."

Steve Ostrowski

CEO, LearningSI

Nagle made a sharp distinction between learning through games and the gamification of learning itself, however, saying that most of the industries his clients operate in largely wouldn't be open to a competitive element for certain tasks.

"For many clients, that could be a bit jarring in terms of what training should actually be," Nagle said. At some levels, a cultural change would have to take place before some would embrace a competitive aspect.

Even so, both Nagle and Ostrowski agreed that the application for new technologies is there, with more possibilities as AR/VR development advances. Ostrowski said LearningSI is already capable of scanning, and recreating, entire facilities in order to allow employees to go on a virtual tour.

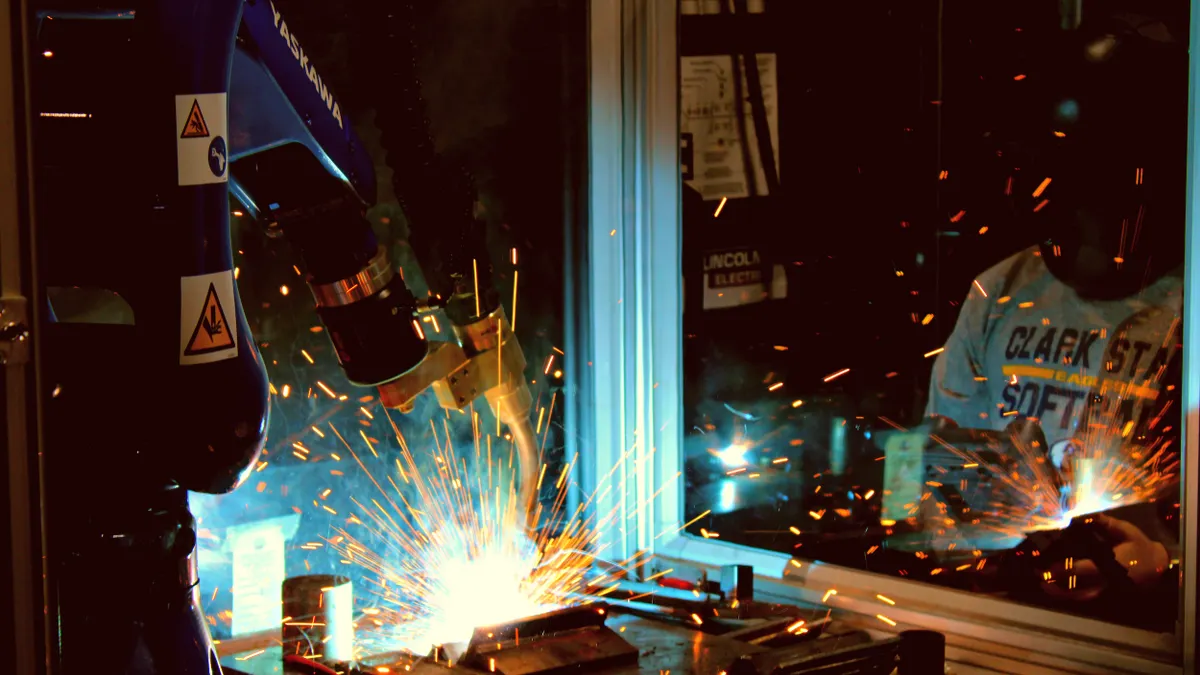

"We even fooled around with building a virtual reality welding simulator," Nagle said. "In the end it kind of worked, it was really cool and worked really well. One of the challenges of welding is that you have to practice and it costs a lot of money and it costs a lot of material to practice."

But even the most cost-saving training can be prove prohibitively expensive for many companies, particularly smaller firms. Both Ostrowski and Nagle said the largest constraint to selling e-learning solutions is cost, on top of demonstrating ROI to executives. How exactly do HR pros do that correctly?

"That's the $54,000 question," Ostrowski said. "I think one of the advantages e-learning gives is that we can build in knowledge checks and tests."

In a similar vein, Nagle discussed the importance of both time-to-competency and trackability, two built-in elements of e-learning programs that can make a huge difference in demonstrating how worthwhile a given training program is.

"Our approach is that you take a practical, realistic approach to those kinds of technology. They should be used in a way that makes sense for the application that the company needs."

Ostrowski also stressed the importance of safety with new technology. "In many industries, if you go into a hazardous area, phones and iPads aren't particularly safe," he said.

Which industries have adapted fastest?

One of the reasons it's particularly difficult for companies in the manufacturing industry to adopt fundamental e-learning, aside from the cost, is the time and resources that are already devoted to compliance training, according to Docherty.

"In general, organizations are spending up to 70% of learning investments in compliance training," Docherty said, "not so much on skills gaps."

Overall, those industries with the largest compliance burdens, like energy and pharmaceuticals, have been the slowest to adopt, in Docherty's experience. Retailers, on the other hand, have been at the forefront of the latest advancements.

Regardless of the industry they're used for, Docherty said, learning programs should improve the onboarding process for new hires.

Ostrowski also reiterated that reducing costs through fundamental training could further demonstrate the feasibility of e-learning in industries that have been slow to adopt.

"It's kind of a law of diminishing returns in some ways," he said, "the better you train, the less [your employees] are going to need to reuse the training. But it still needs to be there in order to be effective."