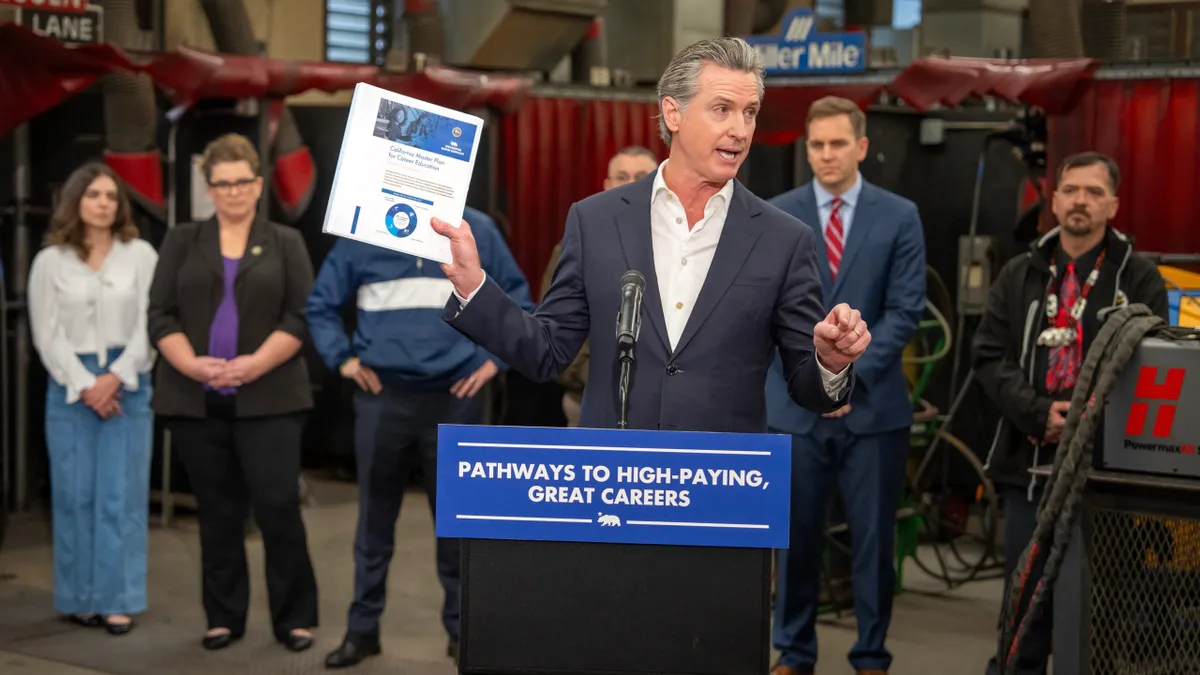

Much of the focus of the post-election job market has been on bringing more blue collar jobs back to North America. Over the decades, many have been lost to outsourcing, international trade and tax deals, and the recession which all but wiped out industrial careers in previously booming regions.

With the future in mind, states are finally getting around to providing generous tax breaks for more industrial firms to resume operations on American soil. With this comes certain challenges, including how to prepare the next generation of industrial workers to perform complex jobs in the age of computer-enabled systems and what to do about projected staff shortages in the industrial sector.

This is where the rubber meets the road in terms of e-learning technology for the industrial sector. Companies need immediate solutions for training the next generation of industrial workers, due to rampant skill shortages that have been developing over the last decade. When factories and plants shut down, young people had no choice but to look elsewhere for careers. Now there are fewer skilled laborers in certain types of industrial work.

Major shortages in industrial talent point to the urgent need for rapid training

According to 2015 research from Deloitte and The Manufacturing Institute, in just the U.S. alone, there is a projected need for 3.5 million manufacturing workers by the year 2025, but nearly 2 million will go unfilled because of serious skill gaps. The survey revealed that 6 out of 10 skilled production jobs go unfilled today due to talent shortages. Jennifer McNelly, president of The Manufacturing Institute said that, “the challenges will continue to grow as retirement changes workforce demographics, the K-12 education system fails to produce enough work-ready candidates with STEM skills, and new technology demands higher levels of training.”

E-learning for industrial workers launches

LearningSI, which is a 20-year provider of customized industrial training programs, recently announced that they’ve launched a new series of e-learning modules that are specifically designed to help firms ramp up new hires quickly to reduce downtime and boost revenues. They point to 3 major factors as leading to the critical nature of industrial training today:

- The aging out of the industrial workforce as Baby Boomers retire and new workers lacking even basis skills to perform tasks

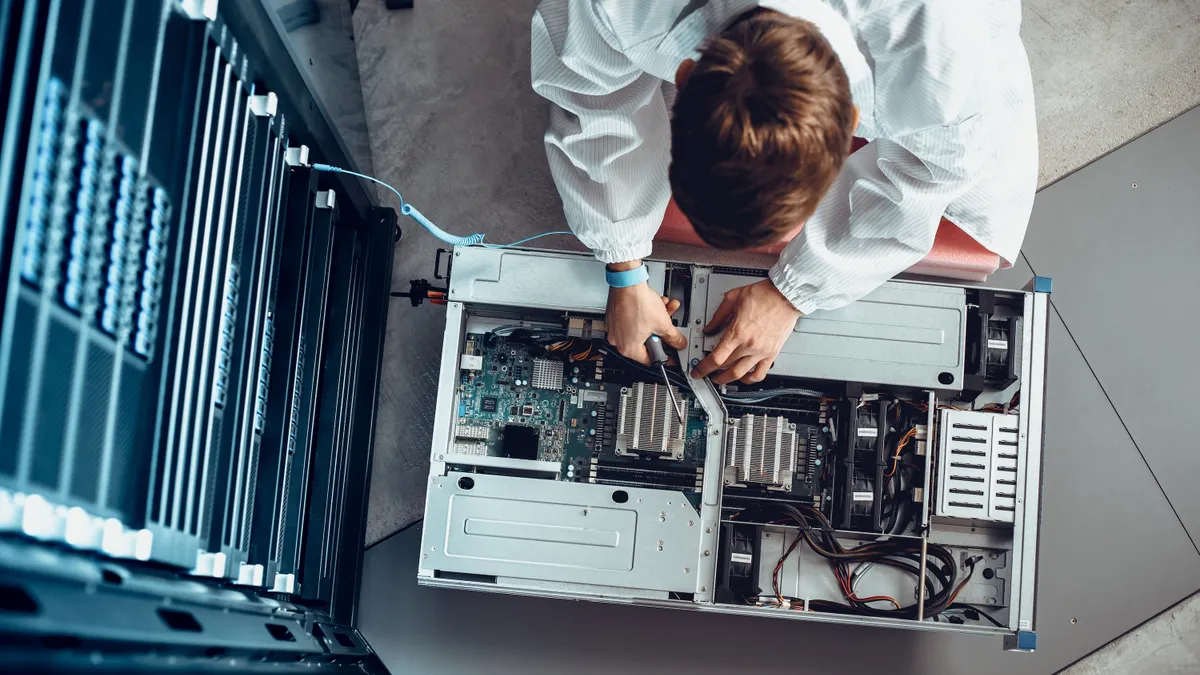

- Brand new processes and equipment that is far more complex than previously seen in manufacturing environments, and require deeper fundamental knowledge

- A young workforce that embraces learning and views it as an employee benefit so they respond well to e-learning methods

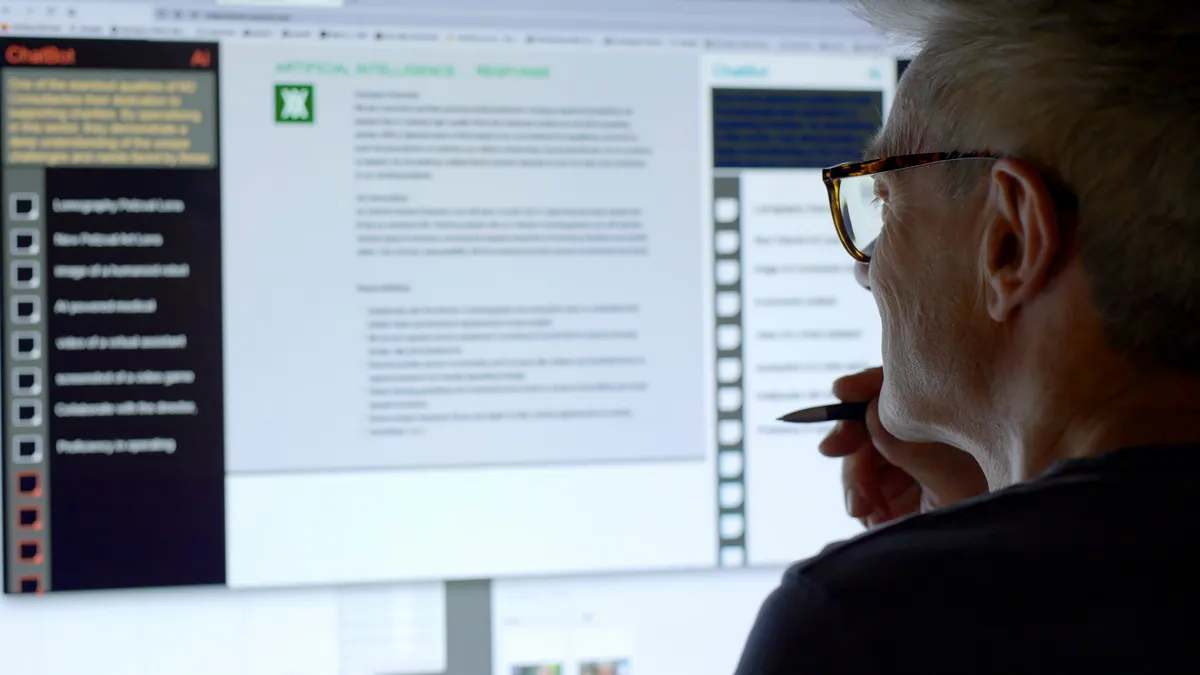

To meet the needs of the industrial workforce, the company is converting its proven instructor-led training programs to e-learning modules. The idea is to make training easier and more cost-effective, while engaging workers in concepts that they need to succeed. Learning programs include reading process and instrumentation diagrams, and future launches will include learning in the basics of electricity, physics, chemistry, and equipment operations.

The unique learning needs of industrial workers

According to Christos Emmanouilidis, Marco Taisch and Dimitris Kiritsis, the authors of the report Advances in Production Management Systems, Competitive Manufacturing for Innovative Products and Services, “demands for enhanced system productivity, availability, safety, quality and customer satisfaction” are driving industrial training to find modern solutions.

Training systems must address the skills that floor technicians need to be agile and collaborative. In other words, training can no longer take place one time in a closed classroom environment or in isolated silos around an organization. Learning facilitated by digitized, on-demand content makes more sense given the ever-changing jobs of industrial workers.

Making the transfer from one generation to the next with e-learning

Knowledge can be lost when an older worker leaves for retirement, creating broken links in the chain of process.

“Industrial firms are losing their trainers whom are experienced workers that mentor new hires,” said Steve Ostrowski, president of LearningSI. He added that, “Our e-learning content developers are made up of these experienced workers, bringing years of collective experience working in their respective industries, to incorporate real-world knowledge into every training program.”

This is essential for any e-learning platform – making sure that all learning modules include the right mix of on-the-job experience and best practices as shared by seasoned professionals. By tapping into the existing knowledgebase, e-learning programs will be more useful in preparing workers for the challenges of a modern industrial world.

The LearningSI model of introducing modern e-learning into a traditionally hands-on environment is something that all companies can learn from. Each industrial firm has a wealth of human capital that not only includes production capability but also different levels of expertise that’s meant to be captured. Delivering training to new hires can help to offset staffing shortages if it starts early and takes place throughout each individual’s career.