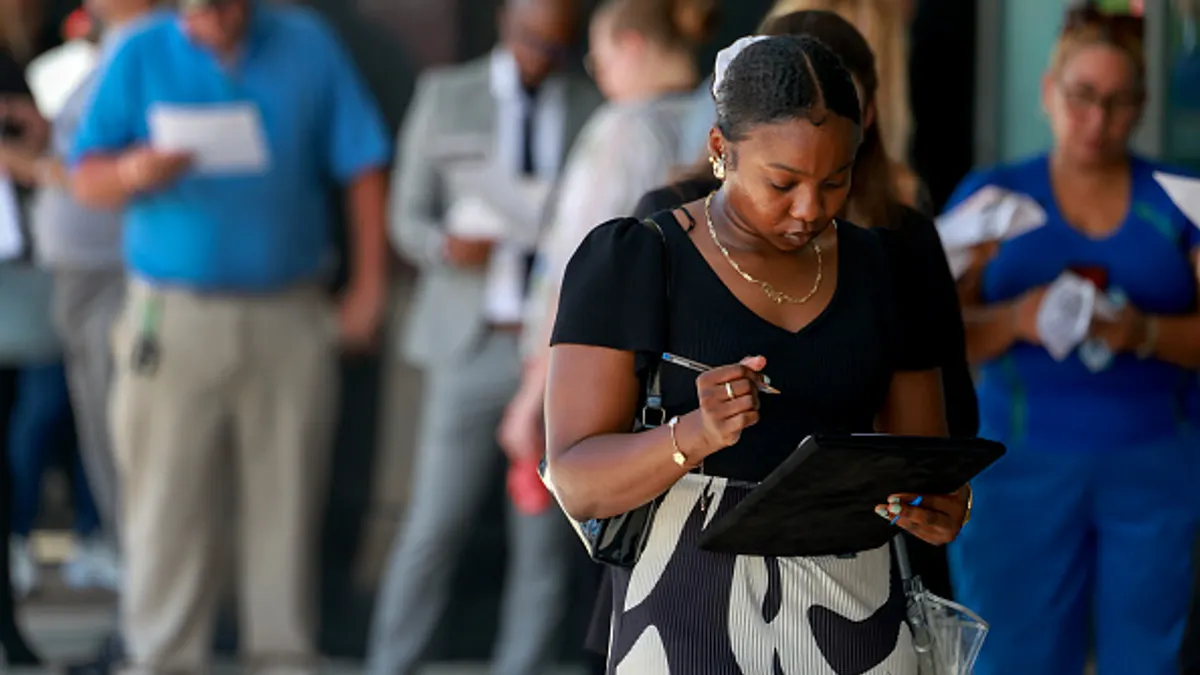

In a recent PwC survey, 62% of manufacturers said they plan to increase their front-line manufacturing workforce in the next year. Despite that high interest, nearly half of survey respondents rated the quality of their company’s approach to creating a positive front-line employee experience as “average” or “below average.”

That gap leaves many manufacturers looking for new ways to recruit and retain this segment of workers.

One of the most effective solutions to create a positive work culture for front-line employees is by seeking direct feedback from workers. However, the survey found only 58% of manufacturers periodically survey their front-line workers about employment engagement and culture, said Anjana Gigi Radhakrishnan, associate director of Workforce Insights and Research at The Manufacturing Institute, which collaborated with PwC for the survey.

This creates a discrepancy between what employers think workers want versus what workers actually desire. That gap widened during the pandemic, when front-line employers faced various hiring challenges, from mandating and encouraging in-person attendance to navigating sudden spikes in demand, said Joanna Cooper, general manager at Daimler Truck North America.

Even as the pandemic fades into the background, retention problems persist. The National Association of Manufacturers’ Q3 outlook survey, found workforce challenges continue to be a top issue for U.S.-based manufacturers of all sizes.

The PwC survey interviewed 108 human resources and operations leaders within the manufacturing industry to identify the workplace needs and preferences of front-line manufacturing workers. Here are the key findings and how manufacturers can effectively hire and retain front-line workers moving forward.

front-line workers want flexible hours

The survey found flexible scheduling to be one of the most impactful factors for creating a positive workplace for front-line workers, at 68% of respondents. Darrin Baldinelli, who has been hiring front-line manufacturing workers across the U.S. since 2006 and now works as a general manager of manufacturing consulting firm Trigo Group, has noticed this firsthand.

“Flexibility has become one of the most desired aspects among candidates seeking front-line positions,” Baldinelli said. This can include flextime, shift work or compressed workweeks in which the employee works for more hours four days a week instead of the usual work hours for five.

This can help manufacturing companies tap into a pool of workers that wouldn’t apply without the ability to personalize their schedules.

“For working parents, it can mean their schedules allow them to pick their kids from school, and for employees in a college program, they can fit classes around their shifts,” Baldinelli said. “On the employer’s side, we find flexible schedules increase workplace morale, engagement and retention.”

A need for better training and mentorship

Better training and mentorship opportunities can significantly boost employee engagement and retention. However, according to the PwC survey, 71% of manufacturers say that they either struggle with or could improve their mentoring programs for front-line workers.

“Many front-line environments have traditionally relied on ‘on-the-job training’, better known as trial by fire,” Cooper said. “Often, the demands of the work environments result in employees being left alone and trying to tackle an overwhelming ramp-up curve in a short probationary period with limited flexibility.”

This can be improved by “designing an onboarding experience that makes workers feel a sense of purpose and belonging, develops skills needed on the job, and establishes confidence in their roles and responsibilities,” Radhakrishnan said. “The first 90 days are crucial for long-term retention.”

In addition, having dedicated mentorship opportunities and career development pathways can help front-line workers understand what they need to do to grow with the company in the long run.

Offering a wide range of benefits

Not every employee is the same, and offering a wide range of benefits can give manufacturing companies the best chance at satisfying varying worker needs.

“No one method works all the time, so strategies must include a full tool belt of solutions, carefully chosen for the current environment and dynamic enough to adapt to change,” Baldinelli said.

For example, there may be times when an attendance bonus will boost worker presence, while sometimes a performance-based reward system may work well.

Beyond what’s typically expected and offered, manufacturers can consider options like extra floating holidays, wellbeing allowances and expanded learning opportunities, including both safety and skill development, said Anthony Abbatiello, U.S. workforce transformation practice leader at PwC. Benefits should extend into well-being, including mental health resources and on-site fitness centers, Abbatiello added.

Addressing childcare needs is also key, Radhakrishan noted. Nearly half of manufacturers that offer dynamic scheduling do so to accommodate workers’ childcare or elderly care needs, according to the survey.

“With childcare costs rising and shortages across the country, manufacturers can address this key need by offering paid parental leave, reimbursed childcare costs, and on-site childcare facilities,” Radhakrishnan said.

In addition to benefits that attract workers, reducing the time of the “application to hire” cycle can be an effective strategy, Abbatiello said.

“Depending on the skill level, manufacturers can improve acceptance rates if cycle times are less than 30 days, and, in some cases, less than 15 days, by leveraging talent intelligence technology,” Abbatiello said.

Correction: In a previous version of this article, Darrin Baldinelli was misidentified. He is the general manager at Trigo Group.