In the fast-paced food processing industry, training employees to work safely and efficiently is a must. But that training can be hard to get right — and employee health often rides on its effectiveness.

For that reason, Tyson Foods has turned to technology to train staff to use equipment and handle foods in a safe manner.

Tyson is working with STRIVR, piloting the use of virtual reality (VR) with general safety/hazard awareness training. Amy Vinson, associate director, safety analytics, health and safety at Tyson Foods, said that as the company investigated a variety of technologies for awareness and training, VR rose to the top of the list. The goal was to reduce injuries by 15%; in fiscal year 2017, Tyson experienced more than a 20% reduction in injuries and illnesses compared to the year prior.

"We are already seeing the far reaching benefits of VR technology," Vinson told HR Dive in an email, "and believe it will be an effective tool for influencing safe behavior of our team members."

Breaking down barriers to safety

The technology also has transcended language and cultural barriers, Vinson said, so Tyson has been able to leverage it across the employee population.

The benefits are mutual for the trainer and employee. "The trainer is able to better understand the task at hand," she said, "while the employee is learning new skills for safety and better work quality." For managers, VR is providing better training for their own work, and they're able to collect data on how team members are responding to a certain process, allowing managers to adjust their approach.

"Without this data from the technology," Vinson said, "these insights would not be possible."

Initial survey results from the pilot program have been overwhelmingly positive; 89% of learners said they felt more prepared after VR training. A positive change in behavior will equate to fewer incidents at work, Vinson believes, and result in healthier, happier employees.

Creating solutions

Tyson's innovation team called in STRIVR to provide demonstrations for leaders and executives. The company worked with Tyson to identify the biggest gaps in its training. And once a specific training program was identified, the organizations worked together to figure out how best to enhance the current training using the platform.

The feedback has been positive, Danny Belch, VP Marketing at STRIVR, told HR Dive in an email, adding that Tyson is already looking to expand into other areas of the business. "They are actually enjoying training and they are better remembering what they learned," he said. "Better training results in better prepared employees and better prepared employees make fewer mistakes and are more productive. So we can look at improved performance and trace it all the way back to using [VR] as a part of training.”

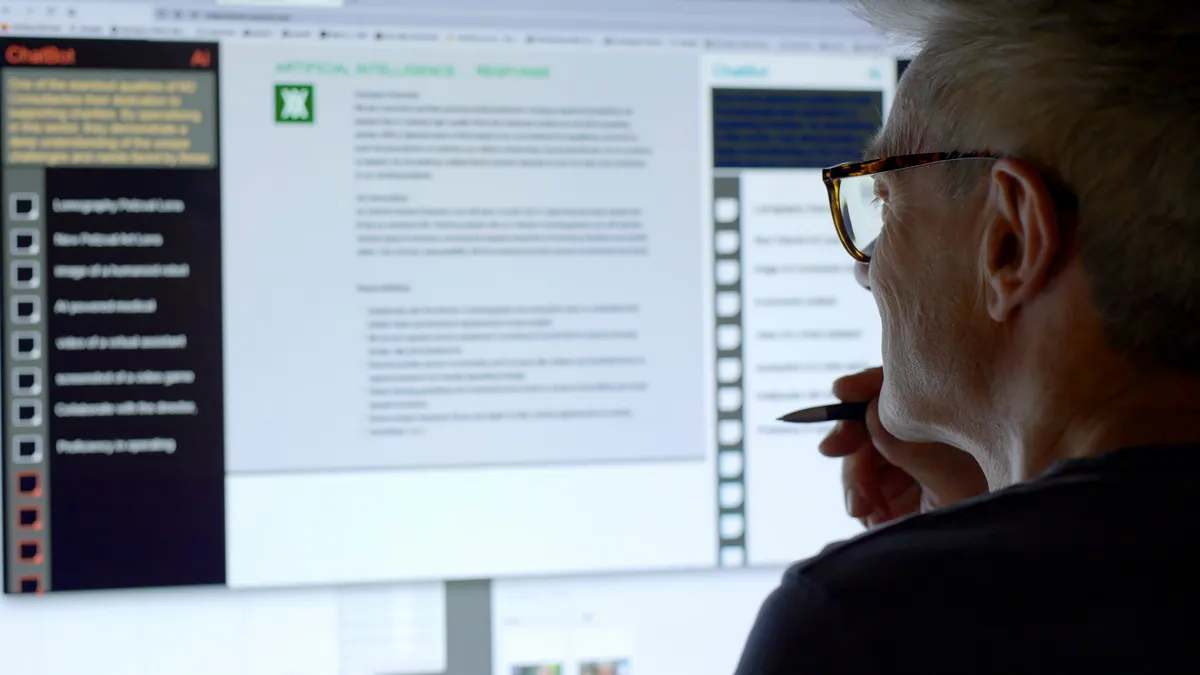

Any industry can use VR or augmented reality (AR) to meet their training needs, Belch said. When his firm meets with a new company, they ask, "how do you train today, what are some of the gaps/inefficiencies, and what would ideally make it better?" From there, they consider whether VR and AR could be a fit. While the tech isn't right for every training need, certain areas like safety training can see powerful successes, he explained.

Still, it's full reach remains to be see. "AR/VR is still relatively new and the technology has more room for growth and maturity," Belch said — but the technology is only going to get better.

Growing use cases

Employers are increasing using immersive VR to teach employees safety, Julie Hiipakka, vice president, learning research leader at Bersin, told HR Dive.

It's particularly useful, she said in an email, “when workers need to do something, and 'doing the something' is hard to practice on the job." It could be because it requires a set of variables that can’t be created, the tools and environment is expensive to use for practice, or that making a mistake would result in injury, damage, or risk to the organization, employee or customer (or all three).

A great use of AR is in manufacturing environments and repair technicians. "If you can rely on technology to serve up information and tips in real time on how to assemble or fix something," Hiipakka said, "you’ll spend less time having to train employees and decrease the amount of time they take to find the answers in a manual or on a tablet."

But AR and VR of course have applicants beyond technical and safety training, she said. "There’s increasing use of VR in ways you might not think about at first — to practice communication with team members, or customer service interactions with patients, clients, customers, and colleagues." The advantage over a typical role play, simulation or video practice is the immersion of a situation that feels and looks real.

Measuring ROI

Hiipakka spoke of a client whose newer, video-based VR systems are so popular they’re in nearly constant (and completely voluntary) use. And while employees love using tech to learn, business is learning as well.

"Using smart glasses, smart scanners, or wearables," she said, "creates the opportunity to track if this technology that companies are using has resulted in faster repair calls, fewer mistakes on the line, reduced repeat escalations or rework." Tracking that data can showcase improved productivity, helping the organization determine the success of the technology.