The 2005 Texas City BP oil refinery explosion, the 2009 Colgan Air Crash, the explosion of the space shuttle Challenger and the nuclear accidents at Chernobyl and Three Mile Island have something in common, according to the Occupational Safety and Health Administration (OSHA) — workplace fatigue was a contributing factor.

Mental and physical fatigue costs the U.S. economy over $136 billion in health-related lost production time, OSHA said. In manufacturing specifically, over 57% of workers have reported being fatigued at work, according to research from Auburn University. The research found workers reported feeling fatigue mostly in the ankles/feet, lower back and eyes.

Managing workplace fatigue isn't just a matter of making the warehouse a safe work environment, but it's good business too. The Warehousing Education and Research Council predicts warehouse labor shortages will be a top issue of 2020.

With workers in the driver seat, they're not going to stick around if they're worked to exhaustion. Wearables have emerged as a solution to monitor fatigue as it's happening, and to predict when it will happen in the future.

"If you're wearing something like a watch or you're walking and picking materials, you can collect information about the worker," Fadel Megahed, assistant professor of information systems and analytics at the Farmer School of Business at Miami University, told HR Dive sister publication Supply Chain Dive in an interview.

Measuring changes in performance

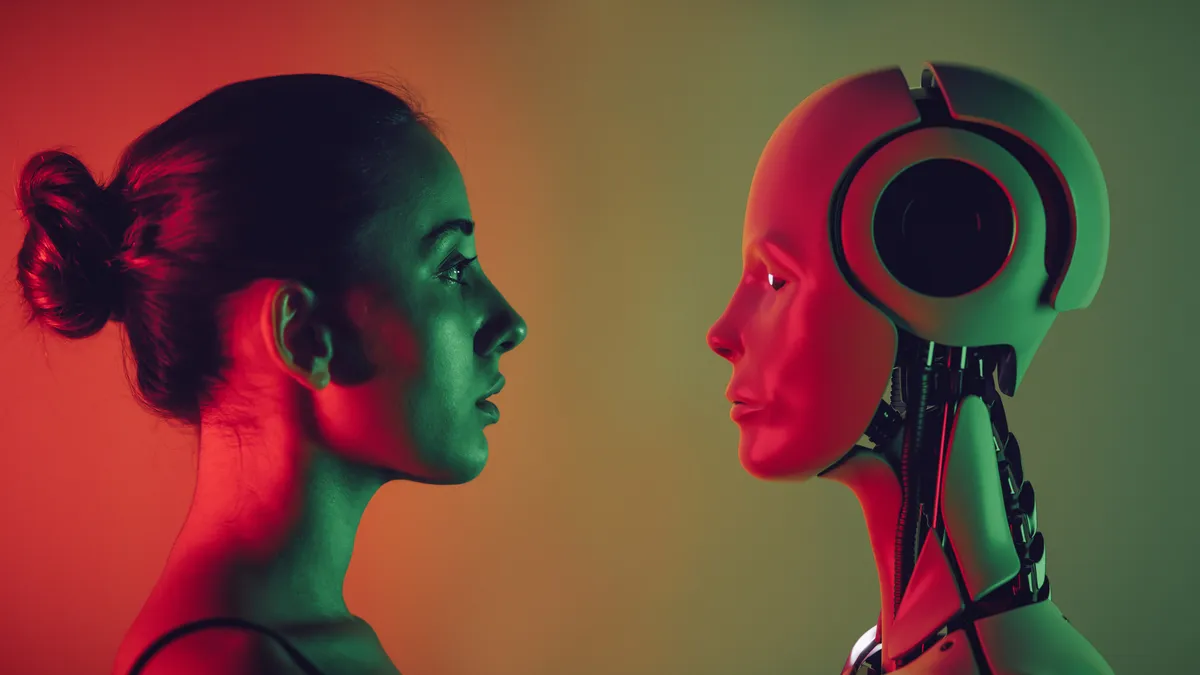

What exactly to measure and how to measure it, Megahed said, is tricky because so many different things about a person can show they're fatigued. It also raises issues of privacy concerns if biometric data is in the mix.

Wearable device makers are putting controls in place to make sure worker privacy is protected. StrongArm Technologies, which makes a wearable called FUSE, said it does not collect biometric data because of worker privacy.

"We're not interested in how hard someone is working. We're really focused on how someone can be safe and how to improve," Michael Kim, chief technology officer and co-founder of StrongArm, told Supply Chain Dive in an interview. He said StrongArm's contract says if it discovers a client misusing data for whatever reason, it can terminate the contract immediately.

"We're not interested in how hard someone is working. We're really focused on how someone can be safe and how to improve."

Michael Kim

CTO and Co-founder, StrongArm Technologies

Most currently deployed devices and research into fatigue monitoring research look to measure fatigue in one of two ways: changes in a worker's performance and changes in a worker's body.

Measuring a worker's performance to determine current and predict future fatigue is something current wearable technology can already do, Eric Allais, president and CEO of PathGuide Technologies, told Supply Chain Dive in an interview.

"When you have employee performance metrics, you know who's doing what by when," he said, which can be combined with when workers check in and out, when they log in and out of work terminals, and their break times. "Sometimes fatigue means you've got folks that drive around but they simulate work. They look like they're working but the performance metrics would tell you otherwise in terms of actually handling the product and shipping."

Setting expectations with metrics

Managers can use these metrics with warehouse management software to determine "what can you reasonably expect," said Allais, in terms of productivity without driving workers into the ground.

That's assuming expectations stay reasonable, which they should even if employers don't have their workers best interest at heart, said Allais. If workers are mistreated, or realize this technology is being used to exploit them, they can go out the door and find another opportunity.

"In an economy with low unemployment, you're going to be trading off those kinds of issues," he said. "The worker in the warehouse is really in more control of their destiny. They can easily walk across the street and do the same kinds of things."

From real-time data to forecasting data

While wearables used for other operations in the warehouse can help detect worker fatigue, wearables are also used explicitly for that purpose.

StrongArm's FUSE platform collects ergonomic data like average maximum lateral velocity and average twist velocity from a worker and combines it with IoT sensor-drawn information about the worker's environment to prevent fatigue and musculoskeletal injuries.

"If you're moving 1,000 boxes in Florida in the peak of summer, that fatigue and potential risk is different than for the same person moving 1,000 boxes a day in Seattle," Kim said.

Megahed is also doing research that could go deeper than just looking at how a body moves to see if a worker is fatigued. Data like stride length, stride height and heart rate could forecast when a worker will be fatigued. This could lead warehouse managers to change scheduling so that employees conduct heavier work earlier in the day. Managers could also change the types of orders workers pick based on what their real-time data shows about the state of their body right now and when models predict they will be more fatigued.

This story was first published in our weekly newsletter, Supply Chain Dive: Operations. Sign up here.